Dynamic simulation of production processes

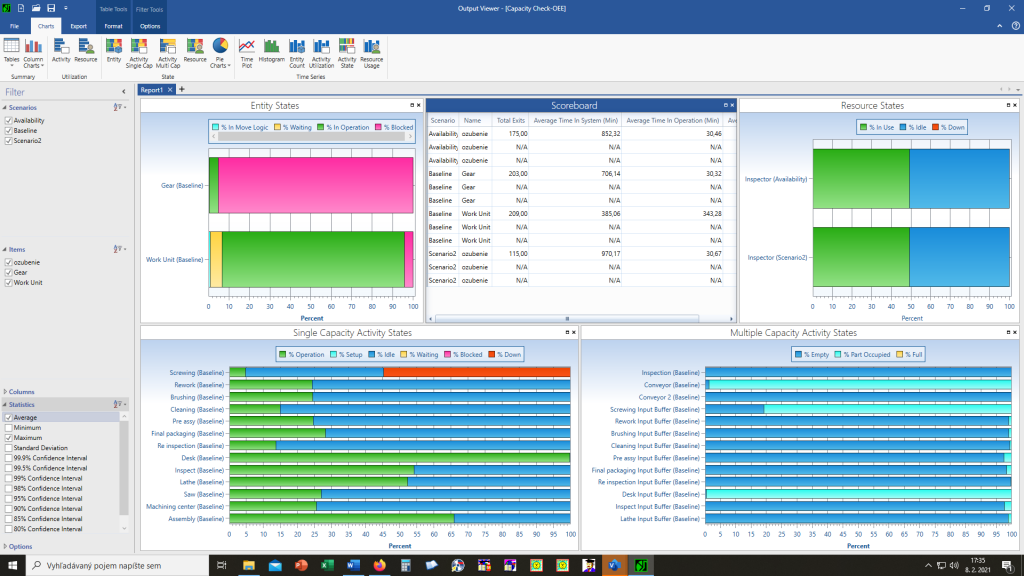

How the manager can answer the question “What if”?

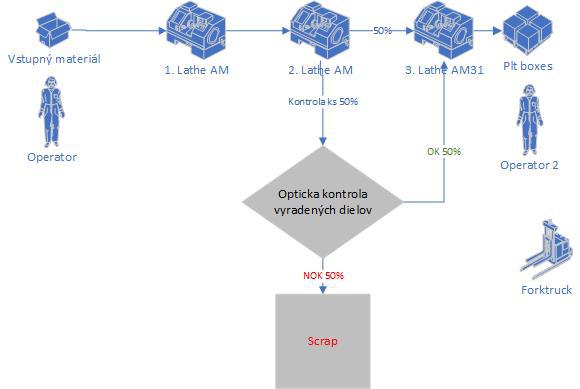

How to achieve a condition where capacity and load are about equal?

How to identify adding value?

How to balance our processes?

What happens if we change process parameters e.g.?

- set up – time

- downtime

- availability of the machines

- performance

- quality

- capacity

- waste reduction

How the changed parameters will affect:

- process throughput

- process profitability

- bottle neck, buffer, inventory

- productivity

- process cost and waste

There are many inputs on production, with direct impact on process performance and profitability. Without correct simulation it’s very hard to answer the question: What if?

And with simulation you may discover many operations / steps that can be replaced by better solutions or even eliminated.